Control systems are everywhere — in your oven, car, air conditioner, and even in industrial robotics. To manage these systems efficiently, engineers use controllers that adjust the output to maintain a desired target value. One of the most common controllers is the Proportional-Integral (PI) Controller.

In this guide, we will cover everything about PI controllers — from the basics to step-by-step calculations, real-life applications, tuning methods, diagrams, and exam/IA strategies. By the end, students will have a complete understanding of this topic.

A PI controller is a type of feedback controller that uses two components:

Proportional (P): Reacts to the current error between the desired setpoint (SP) and the process variable (PV).

Integral (I): Reacts to the accumulated error over time, removing any residual error left by the proportional action.

Error formula:

Error = Setpoint (SP) − Process Variable (PV)

Key takeaway:

The P part reacts quickly to deviations.

The I part corrects any remaining differences over time.

Example:

Imagine you are heating water to 60°C. The P action increases the heater power immediately if the water is below 60°C. If the temperature remains slightly below 60°C due to constant heat loss, the integral action gradually increases heater power until the temperature reaches 60°C exactly.

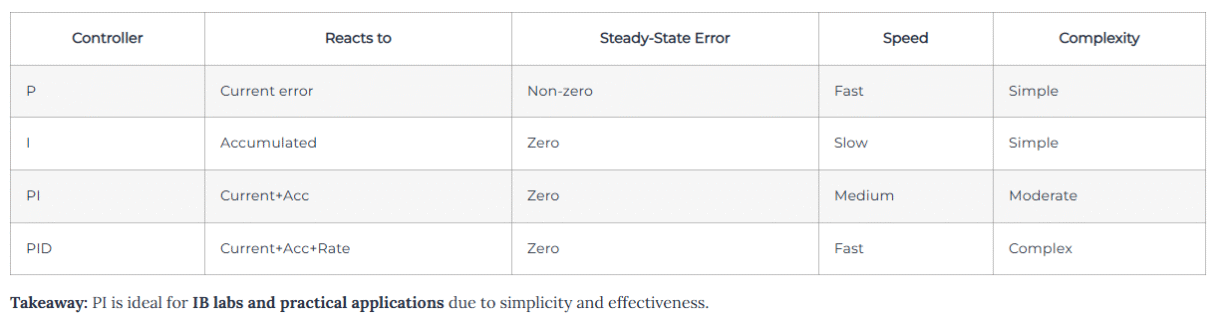

Using only P control can leave a steady-state error — the system never reaches the exact setpoint. Using only I control is too slow for practical use. The PI controller balances speed and accuracy:

Fast initial response: Proportional

Zero steady-state error: Integral

Practical Intuition

Consider driving at 60 km/h:

If your speed drops to 55 km/h, the proportional action increases acceleration immediately.

If you remain slightly below 60 km/h, the integral action gradually increases acceleration until exactly 60 km/h.

Thus, PI control gives smooth, accurate, and stable control.

The proportional component is calculated as:

P_output = Kp × error

Where Kp is the proportional gain.

How it works:

High Kp → system reacts strongly to errors; may overshoot

Low Kp → system reacts slowly; may never fully correct

Graphical representation:

Plot SP and PV vs. time

P-only response: quick rise but slight steady-state error remains

Error = 100 − 90 = 10

P_output = 2 × 10 = 20

The output of 20 units (volts, percentage, etc.) is applied to the system actuator.

The integral component addresses accumulated error over time:

I_output = Ki × ∫ error dt

Ki = integral gain

∫ error dt = cumulative error over time

Key points:

Eliminates steady-state error

Works slower than P

Too high Ki → overshoot; too low Ki → slow correction

Suppose error = 2°C over 10 seconds, Ki = 0.5

I_output = 0.5 × (2 × 10) = 10

This output slowly corrects the residual error.

Combined output formula:

Output = Kp × error + Ki × ∫ error dt

Workflow:

Measure PV

Calculate error (SP − PV)

Compute P_output

Compute I_output

Sum P + I → actuator

System responds → new PV

Repeat

Insight:

P reacts immediately

I removes residual errors

This dual-action approach is what makes PI control widely used.

Continuous-time formula:

u(t) = Kp × e(t) + Ki × ∫ e(t) dt

Where:

u(t) = controller output

e(t) = SP − PV

Kp = proportional gain

Ki = integral gain

Discrete-time formula (useful in IB IAs / simulations):

u[n] = Kp × e[n] + Ki × sum(e[0..n] × dt)

n = discrete time step

dt = time interval

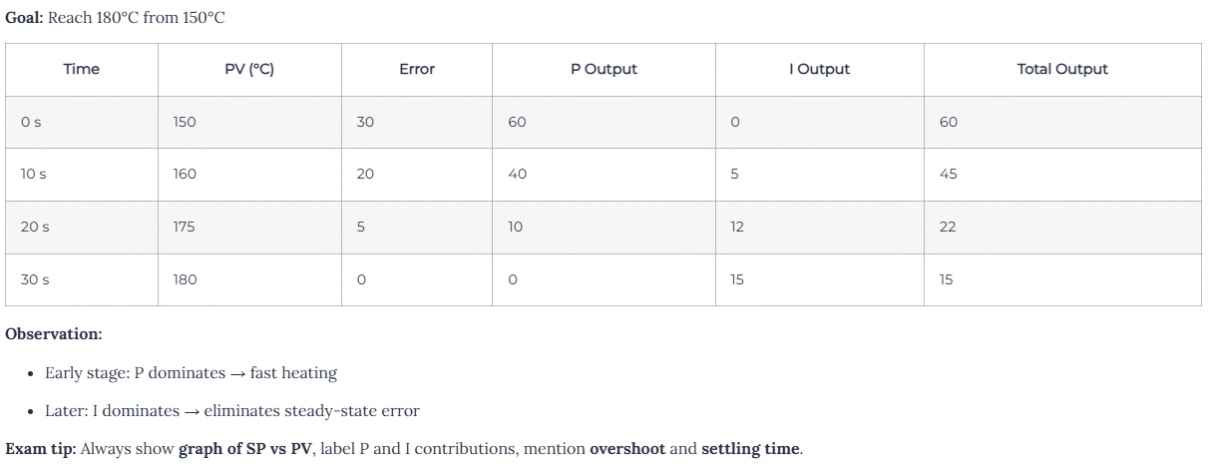

Goal: Maintain 2000 rpm under changing load

Load increases → RPM drops → error rises

P_output immediately increases voltage to motor

Small remaining error → I_output gradually eliminates it

Motor stabilizes at 2000 rpm

Graph suggestion: Plot SP, PV, P contribution, I contribution over time. This helps visualize how PI balances speed and accuracy.

Setpoint (SP): 100°C

PV: 90°C

Kp: 2

Ki: 0.5

Accumulated error: 10°C·s

Step 1: Error = SP − PV = 10

Step 2: P_output = Kp × error = 2 × 10 = 20

Step 3: I_output = Ki × accumulated_error = 0.5 × 10 = 5

Step 4: Total_output = 20 + 5 = 25

Interpretation: 25 units applied to the actuator will bring PV closer to SP.

Stepwise Method

Set Ki = 0

Increase Kp until fast response without oscillation

Slowly introduce Ki to remove steady-state error

Check for overshoot and stability

Adjust Kp and Ki iteratively

Consider anti-windup for actuator limits

Ziegler–Nichols Method (optional, advanced)

Increase Kp until sustained oscillation occurs (Ku)

Measure period of oscillation (Tu)

Set Kp = 0.45×Ku, Ki = 1.2×Kp/Tu

💡 For IB students: Stepwise tuning + plots + tables is sufficient.

Confusing I and D (integral vs derivative)

Not specifying units for Kp, Ki

Ignoring anti-windup

Using P alone → leaves steady-state error

Overestimating Ki → overshoot

✅ Always include graph, calculation, and explanation in IA or exam response.

Include block diagram of PI controller

Show step response graph

Label P and I contributions

Include numerical table of outputs

Discuss overshoot, settling time, and limitations

Mention real-world applications

💡 This demonstrates understanding, analysis, and evaluation — key for IA marks.

PI Block Diagram: Error → P → sum → Output; Error → I → sum → Output

Step Response Graph: SP vs PV over time

Contribution Graph: Show P and I contributions

Tuning Flowchart: Stepwise method

Tip: Use Excel, Google Sheets, or drawing software. Include labels and units.

Oven temperature control

HVAC systems

Motor speed and position

Robotics

Pressure and flow regulation

Medical devices (infusion pumps)

Takeaway: PI control is used anywhere precision regulation is needed.

Use Excel or Python for step-by-step simulations

Discrete-time formula:

u[n] = Kp * e[n] + Ki * sum(e[0..n]*dt)

Plot SP, PV, P, I contributions

IB IA tip: Include screenshots of simulation and describe trends.

Anti-windup techniques prevent integrator from overshooting

Sampling time (dt) affects discrete-time controller accuracy

Noise filtering can be necessary in derivative systems (PID)

Include keyword naturally in H1, first paragraph, subheadings, FAQ

Use people-first language — helpful content for students

Add diagrams with alt text

Include internal links: IB Math integration, Physics control systems, IA samples

Use FAQ schema for Google results

Ensure mobile-friendly, fast-loading page

Controller using current error + accumulated past error to reach and maintain setpoint.

PID adds derivative term to anticipate trends; PI is simpler.

When integral accumulates too much while actuator is saturated → overshoot. Prevent with anti-windup.

Temperature, motor control, robotics, pressure regulation, medical devices.

Stepwise method: tune Kp first, then Ki, monitor response, adjust iteratively.

Yes. Use discrete-time formula and plot SP, PV, P, I contributions.

IB Demystified is a trusted online learning platform led by certified IB examiners and educators.

© 2026 IB Demystified LTD

ALL RIGHTS RESERVED.

Powered by AfiaDigital

WhatsApp us